Mochini oa Leqhoa oa Poleiti o nang le Mosifa oa Poleiti ea Mouoane

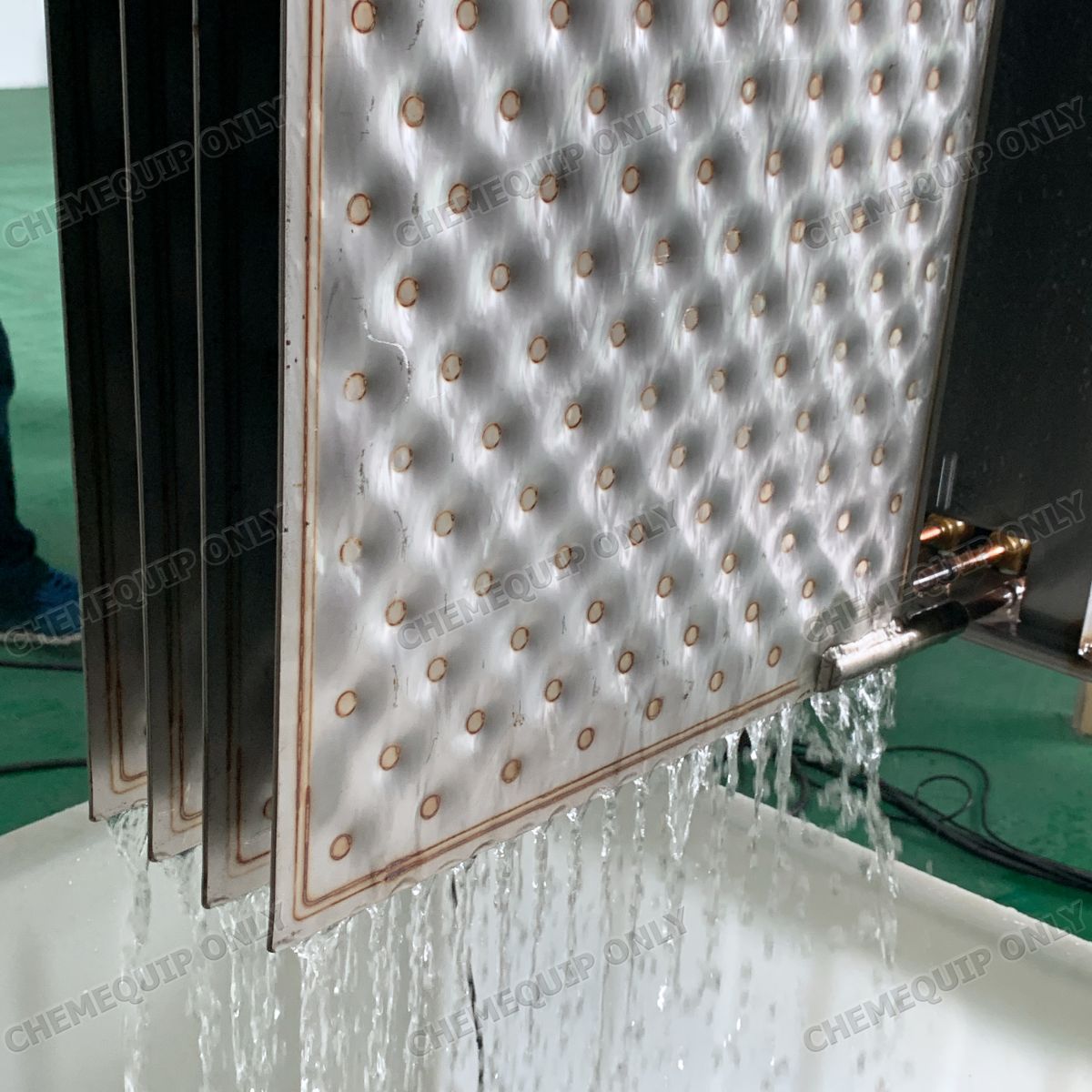

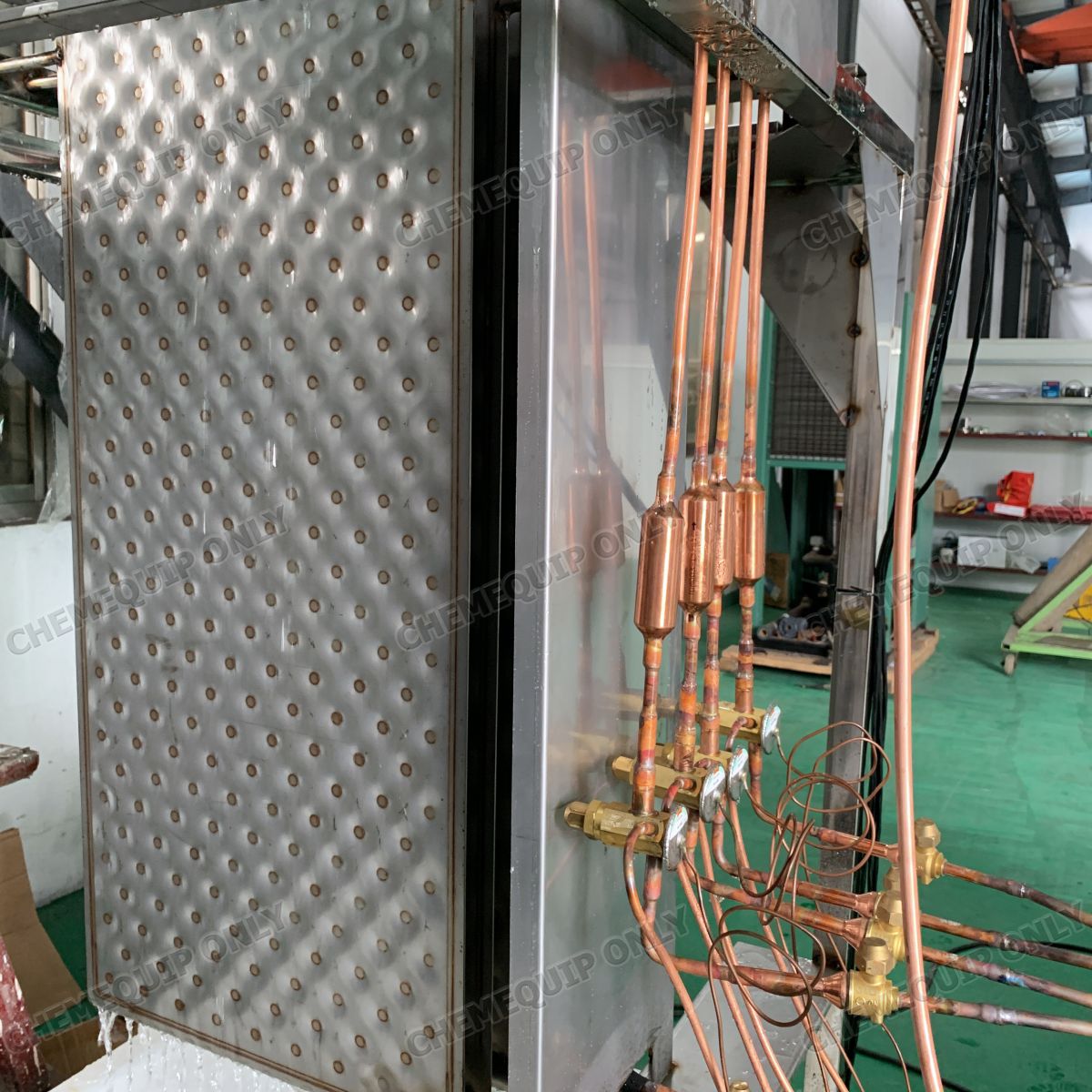

Karolong e ka holimo ea Mochini oa Leqhoa oa Plate, metsi a pompeloa 'me a oela ka masoba a manyenyane ebe butle-butle a phalla ho ea Platecoil® Laser Welded Pillow Plates. Sepholi se ka har'a Lipoleiti tsa Laser se pholisa metsi ho fihlela a hoamisitsoe. Ha leqhoa mahlakoreng ka bobeli a poleiti le fihla botenya bo itseng, joale khase e chesang e kenngoa ka har'a Lipoleiti tsa Laser, e leng se etsang hore lipoleiti li futhumale 'me li lokolle leqhoa lipoleiting. Leqhoa le oela ka tankeng ea polokelo 'me le robeha likotoana tse nyane. Leqhoa lena le ka isoa ka screw ea ho tsamaisa ho ea sebakeng seo le se batlang.

1. Indasteri ea lino tse tahang bakeng sa ho pholisa lino tse bonolo.

2. Indasteri ea ho tšoasa litlhapi, ho pholisa litlhapi tse sa tsoa tšoasoa.

3. Indasteri ea konkreite, ho kopanya le ho pholisa konkreite linaheng tse nang le mocheso o phahameng.

4. Tlhahiso ea leqhoa bakeng sa polokelo ea mocheso.

5. Indasteri ea lebese.

6. Leqhoa bakeng sa indasteri ea merafo.

7. Indasteri ea likhoho.

8. Indasteri ea nama.

9. Semela sa lik'hemik'hale.

1. Leqhoa le teteaneng haholo.

2. Ha ho na likarolo tse tsamaeang tse bolelang hore tlhokomelo e nyane haholo.

3. Tšebeliso e tlase ea matla.

4. Tlhahiso e phahameng ea leqhoa bakeng sa mochini o monyenyane joalo.

5. Ho bonolo ho e boloka e hloekile.