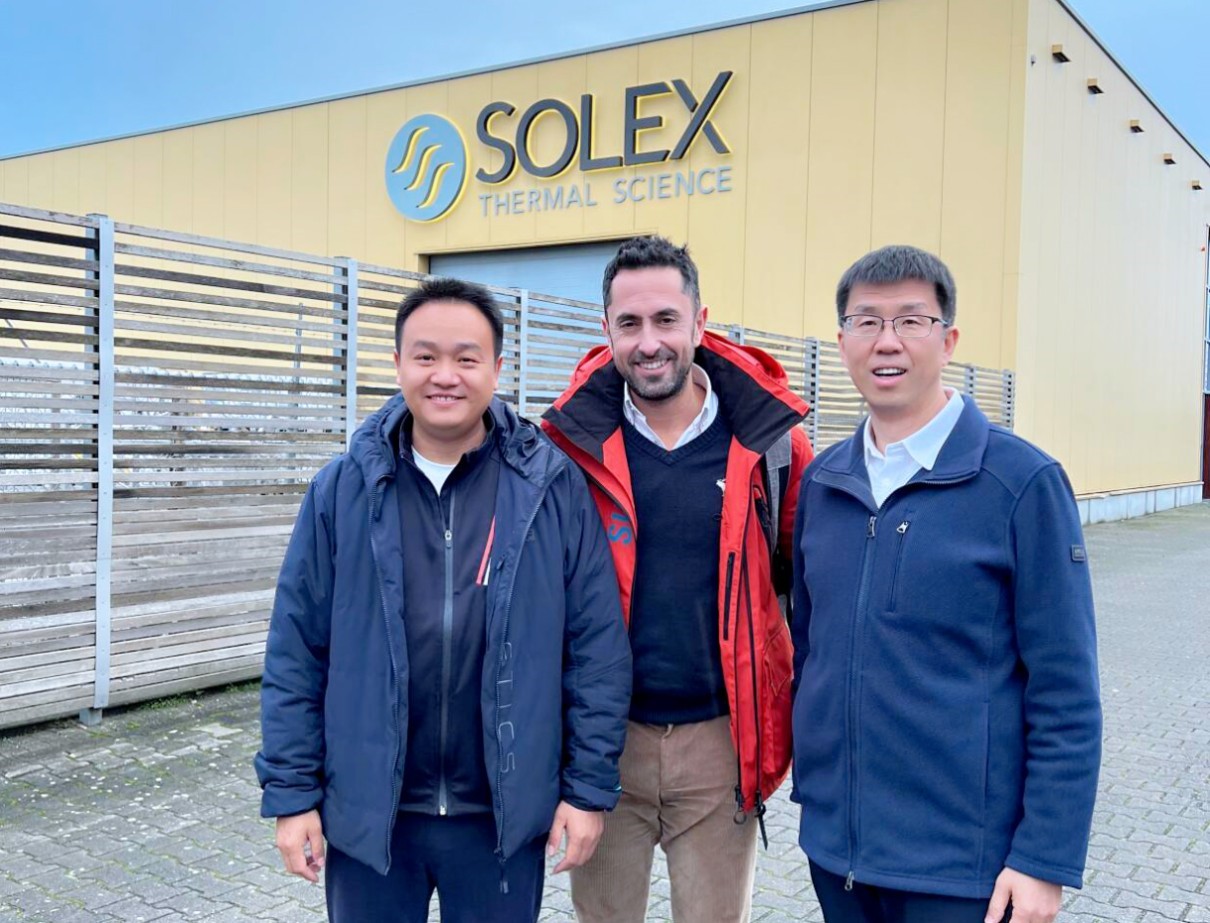

On December 13th local time, Chemequip Industries visited the European regional headquarters of our global partner, Canadian Solex Thermal Science lnc., located in the Netherlands, which serves as their European manufacturing base. During the inspection, a preliminary introduction and discussion on the global cooperation of Chemequip company's Pillow Plate, Dimple Jacket, Static Melting Crystallizers, Falling Film Chiller, Ice Bank, Flue Gas Heat Exchanger, Plate Coil Heat Exchanger, Clamp on was conducted. Solex's global CEO and senior vice president, among others, accompanied the inspection and communication.

At the same time,Solex discussed the newly launched marine heat exchanger, the newly acquired company's pipe heat exchanger, and other new technologies introduced this year. During the meeting, Solex hopes that Chemequip will promptly promote the new products launched this year and the heat pipe heat exchangers of the acquired company to the Chinese market. This visit has increased mutual trust and is also the first visit by Chemequip to Solex after the relaxation of the epidemic.

This visit is a very meaningful experience. Through it, we can deepen our understanding of Solex corporate culture and values, which helps to establish a closer partnership. In addition, it also allows us to have a better understanding of Solex products and services, as well as the general market competition environment. All of these information has a positive impact on our future cooperation and business development. Moreover, through face-to-face communication, we can better establish a closer business relationship.

Pillow Plate Heat Exchanger is a type of heat exchanger that consists of multiple parallel plates welded together to form a series of pillow-shaped channels. The fluid flows through these channels and undergoes heat exchange with the opposite fluid flowing in the adjacent channels. This design allows for efficient heat transfer and is commonly used in industries such as food and beverage processing, pharmaceuticals, and HVAC systems. The pillow plates provide a large surface area for heat transfer and can be easily customized to fit specific process requirements. This type of heat exchanger is known for its high thermal performance, compact size, and ease of maintenance.

Post time: Dec-13-2023