Dimple Jacket Applications in Chocolate Industry

Producing good quality chocolate requires a very precise production process. The cooling and heating of the cocoa, during mixing, crystallization and so on, requires the utmost accuracy. With Clamp-On heat exchanger (Dimple Jacket) the temperature can be regulated evenly and consistently. In the later processing of chocolate in the desired form, it is important that the temperature does not rise too high. After all, chocolate cannot melt. In the most advanced chocolate cooling tunnels, our Pillow Plates are processed for a good cooling of tempered and processed chocolate products.

Consistent Heating of Chocolate Tanks

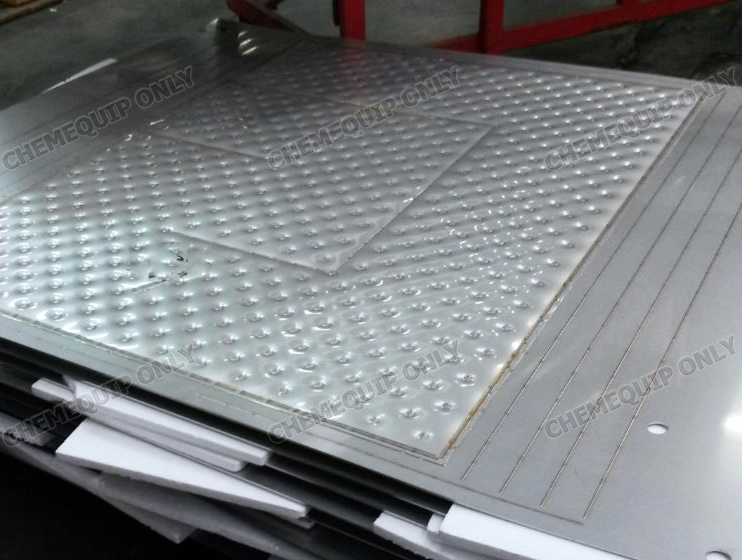

After burning, the cocoa pieces, the nibs, are ground. The fat that is in the cocoa pieces is called cocoa butter. By grinding the nibs very finely, this cocoa butter is released. This is done in cocoa mass tanks where the nibs are melted and ground at a temperature higher than 35 °C. Cocoa mass tanks can be coated with Pillow Plates to keep the temperature constant, during grinding and melting.

Cooling of Chocolate Tanks

The melting of chocolate must be done slowly and at low temperature, with a not too high temperature difference. If the temperature of the chocolate becomes too high during melting, aromas disappear and the couverture becomes granular and dull after stiffening. The cocoa tank must therefore be heated to a uniform temperature. In many cocoa tanks you can now find Pillow Plates. This ensures consistent heating of the tank to the temperature you want. The chocolate will be heated indirectly, slowly and evenly. This indirect form of heating has the effect of au bain-marie.