Pillow Plate Applications for Milk Cooling

Here is a part of our series about Pillow Plates Heat exchangers, are emerging as a highly sought-after food cooling solution. Compared to traditional heat exchangers, they are relatively new, but their unique "pillow-shaped" design provides greater flexibility and efficiency in heating and cooling systems. As a result, pillow plate heat exchanger are becoming increasingly implemented in the dairy industry. These fully welded heat exchangers represent a highly versatile technology that is changing the game for many businesses.

Falling Film Chiller Produce 0~1℃ Ice Water in Dairy Plants

Ice water of 0~1ºC has a very high cooling capacity, which means that heat can be transported at relatively low flow rates compared to other coolants. Our Falling Film Chillers as hydro coolers are an unbeatable alternative in the cooling of dairy plants with a more effective and faster cooling of the product with lower energy consumption. Very high heat transfer coefficients are achieved, while ice water temperatures close to zero degrees (0~1ºC) can be reached without compromising the physical integrity of the equipment and without the need for sophisticated regulation and control methods to prevent the water from freezing, as is required in other systems.

0~1℃ ice water cooling in the dairy industry is the most hygienic, effective and safest method of lowering the temperature of milk products under the hygienic conditions required by the food industry. Ice water has a very high cooling capacity, which means that heat can be transported at relatively low flow rates compared to other cooling media. The thermodynamic parameters and the technical properties of the water cycle are favourable, so that very high heat transfer coefficients are achieved. The production of cold water and the cooling with this water have in any case the physical limit of the freezing point of water. On the one hand, one wants to work with water at temperatures as close as technically possible to its freezing point in order to lower the temperature of the product to be cooled as much as possible, but on the other hand, problems with ice formation increase as they approach zero. In addition, ice formation is associated with increased energy consumption, as the ice acts as an insulating layer and reduces the heat transfer coefficients. For the production of ice water with a falling film chiller, it allows to reach temperatures as close as possible to zero degrees Celsius, but insensitive to ice formation.

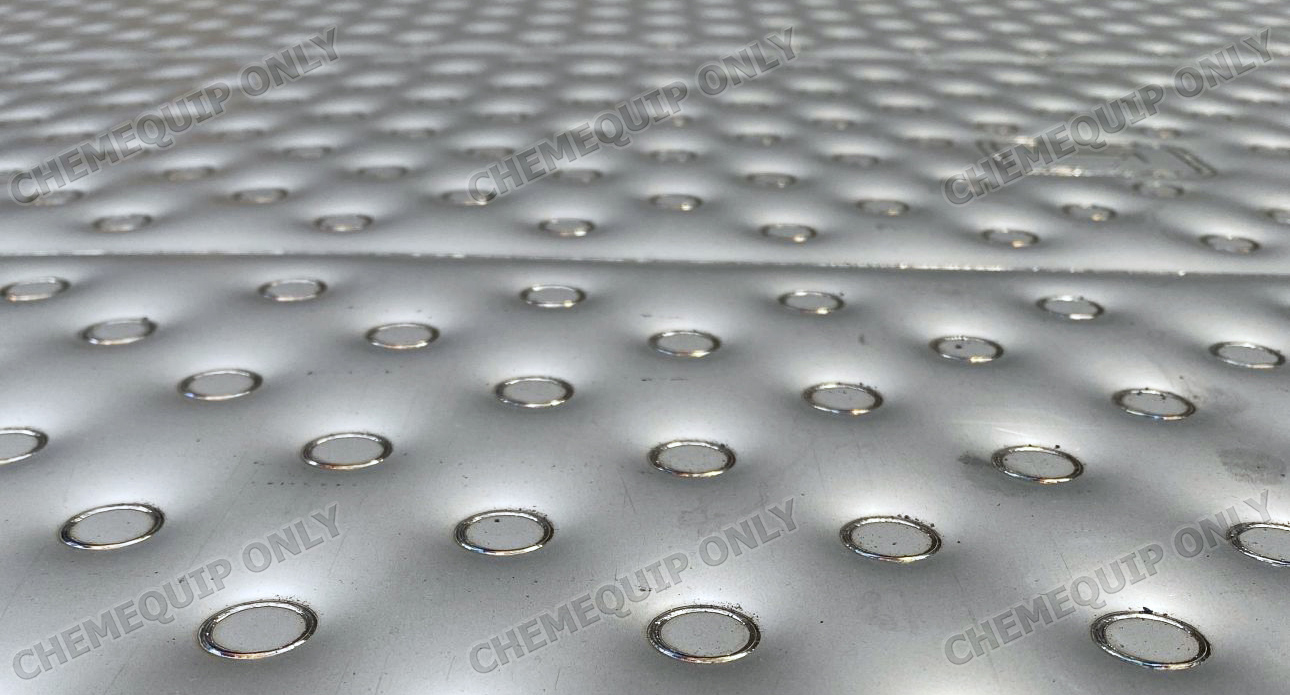

Dimpled Jacket for Milk Cooling Tank

Chemequip is a manufacturer of Dimpled Jacket for milk cooling tanks. In order to deliver quality milk products, it is important that the vessel is cooled evenly and to the right temperature. In addition, the cooling of dairy products must comply with all kinds of legal regulations. This applies to milk coming directly from the cow as well as for dairy products such as yoghurt, custard, cheese or cream which are processed in the dairy factories. Chemequip has nearly 20 years of experience in the process-oriented design and production of Pillow Plates for the dairy industry.

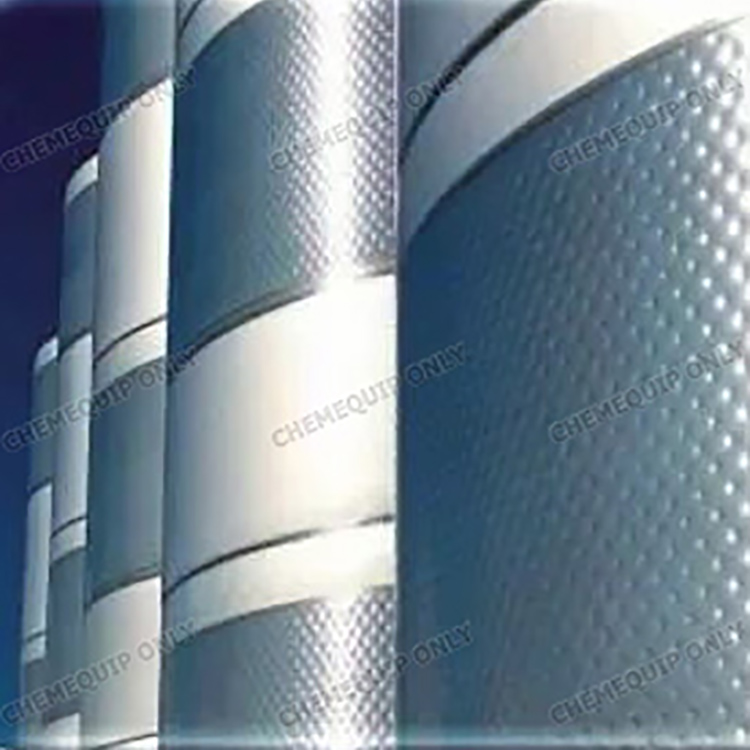

Milk Cooling Tanks at the Farms

When cows are milked, the milk has to be cooled from 35° C to 4 °C within 3 hours. Depending on the number of times per day that you milk, you calculate how much cooling surface is needed (Dimpled Jacket/Clamp-On) to cool the milk within the established time limit. Many smaller dairy farms in Western Europe merge into bigger farms with a larger stock of cattle. At these companies, traditional milk tanks are slowly being replaced by larger milk silos.

Advantages of Using Dimpled Jackets(Clamp-On) for Milk Tanks

1. Can be mounted on the surface of existing tanks or container to provide the heating or cooling.

2. Flexible welding process ensures very efficient heating and cooling.

3. Optimal heat transfer due to turbulent flow in the dimpled jacket.

4. Available in most materials, like stainless steel SS304, 316L, 2205 Hastelloy titanium and others.

5. Custom-made size and shape are available.

6. Low maintance and operating cost.

7. Sturdy and Safety.