Falling Film Chiller Produces 0~1℃ Ice Water

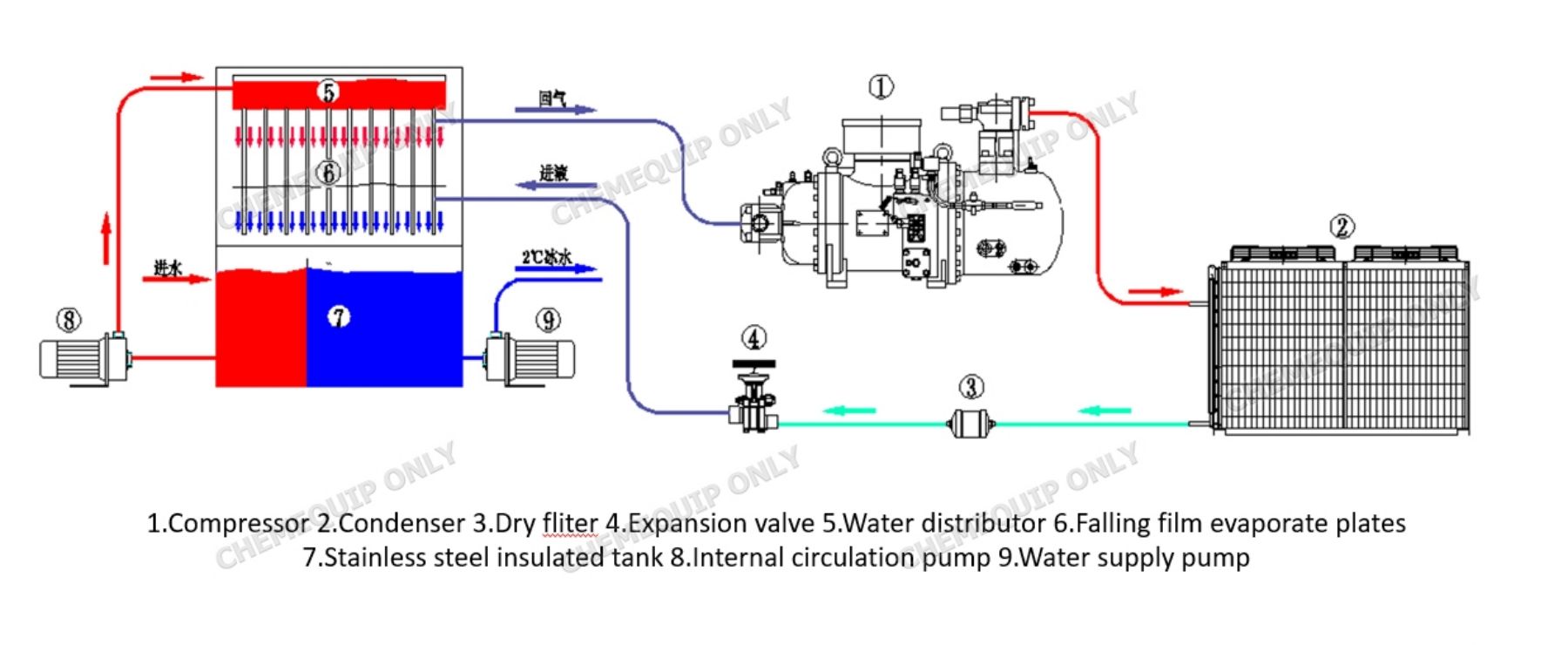

Falling film chiller mainly consists of pillow plates evaporators and stainless-steel cabinet. It is a heat exchanger that cools water to your desired temperature, and this ice water is normally used to cool large quantities of product in a short amount of time. In the falling film chiller, the pillow plate evaporators transfer heat from a thin film of liquid falling on the outside of the plates. The refrigerant is passing through the internal channels of the pillow plates. Cooling of liquids over a wide temperature difference can easily be achieved.

Warm chilled water is pumped into the distribution tray and flows at a controlled rate from an over panel distribution through even down the outside of the Platecoil plates(also called pillow plates) into the tank. The internal channel of Platecoil plates passes through the cooling medium, and the warm chilled water and cooling medium exchange heat indirectly. The warm chilled water is cooled to the required temperature by the cooling medium. The cooling medium usually uses Freon, Ammonia, Glycol, as well as special constructions that can be operated with glycol present of the refrigerant.

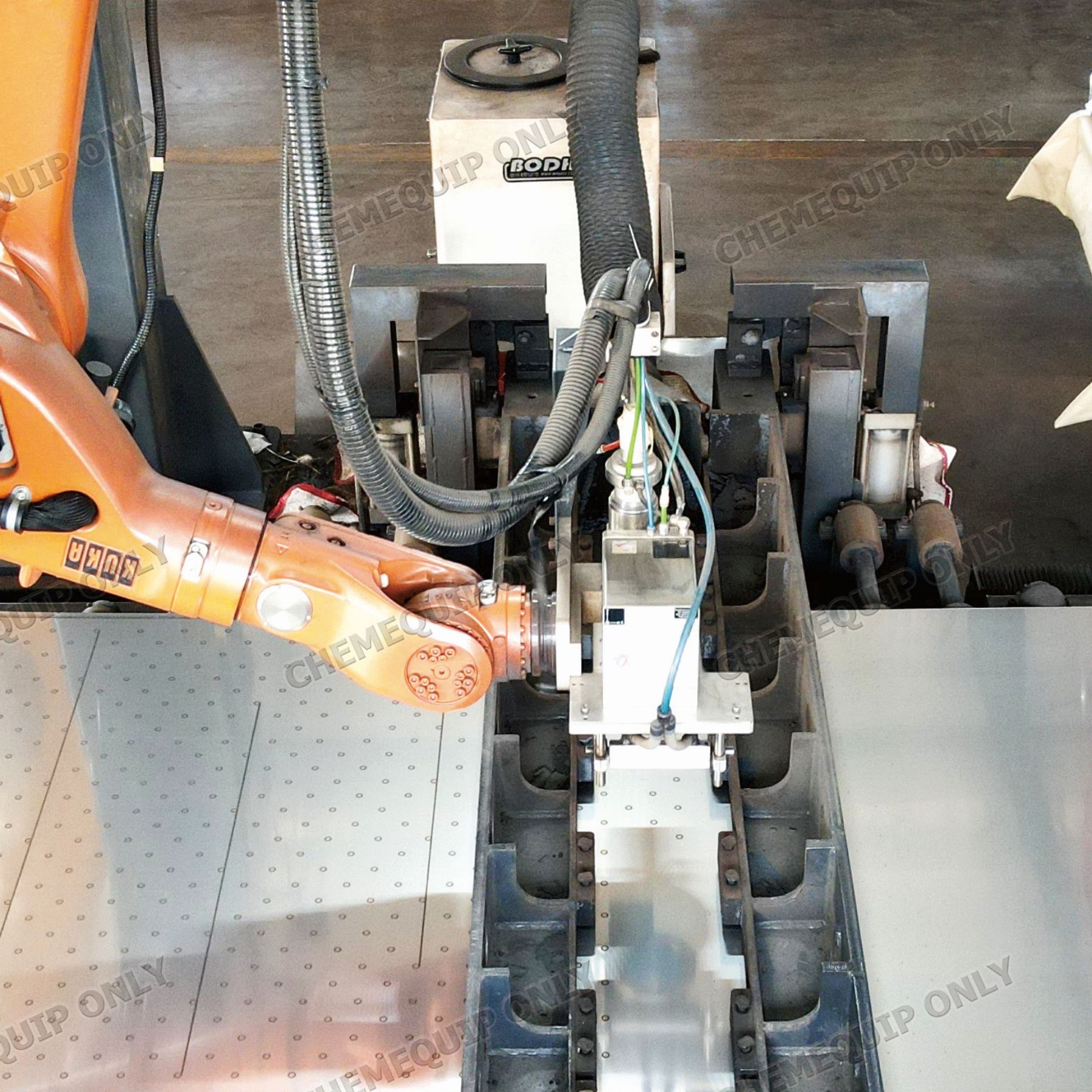

Platecoil plate is a special heat exchanger with a flat plate structure, formed by laser welding technology and inflated, with highly turbulent internal fluid flow, resulting in high heat transfer efficiency and uniform temperature distribution. lt can be designed and manufactured in different shapes and sizes according to customer's requirements. The exterior of the Platecoil plate is cabinet which designed with water distribution tray, outer door and so on. It can easily be cleaned, thanks to accessibility from all sides and space between the pillow plates evaporator.

|

Milk cooling production |

Blanching vegetables |

Poultry industry |

|

Cooling mussels/shrimp |

Cheese production |

Fish processing industry |

|

Bakery production |

Meat processing industry |

Construction industry (concrete) |

|

Chemical industries |

Pharmaceutical industries |

Coconut milk cooling |

1. Continuous and stable supply of 0-1°C water.

2. No mechanical distortion even when icing-up.

3. High heat transfer coefficient and low operating cost.

4. Platecoil plate structure for easy cleaning and maintenance.