Pillow Plate Applications for Fruit and Vegetables

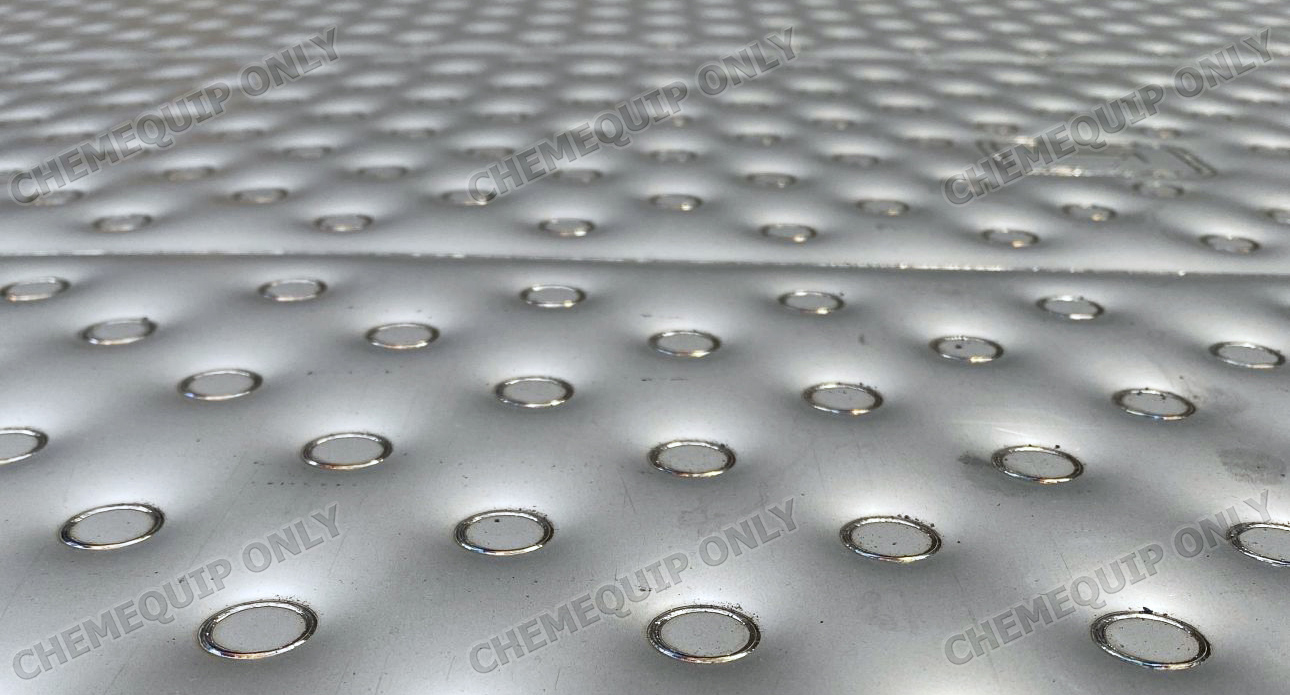

Here is a part of our series about Pillow Plates Heat exchangers, are emerging as a highly sought-after food cooling solution. Compared to traditional heat exchangers, they are relatively new, but their unique "pillow-shaped" design provides greater flexibility and efficiency in heating and cooling systems. As a result, pillow plate heat exchanger are becoming increasingly implemented in the food industry. These fully welded heat exchangers represent a highly versatile technology that is changing the game for many businesses.

Falling Film Chiller in Use for Effective Cooling of Fruit and Vegetables

Our Falling Film Chillers as hydro coolers are an unbeatable alternative in the cooling of fruit and vegetables with a more effective and faster cooling of the product with lower energy consumption. Easier processing of larger harvest produce due to continuous flow over the conveyor belts.

Why Does Running a Vegetable Through Cold Water Extend its Shelf Life? When to Use Hydrocooling?

At the time of harvesting from the tree, bush or soil, the ageing of the product begins, especially at high summer ambient temperatures. The requirements for an optimal cooling system should be aimed at cooling down the product from the heat as quickly as possible after harvesting. If the crop is cooled directly with cold water or brine, this type of cooling is called hydro-cooling. For all fruits and vegetables, immediate cooling should take place directly after harvesting in order to achieve the highest product quality on the customer side and guarantee fresh produce.

Cooling Fruits and Vegetables? Hydro Cooling with Ice Water – Fast & Effective

Hydro-cooling is extremely fast and effective even in relation to large quantities of product to be cooled and large product dimensions. The product can be stored after in the cold room for storage before transported to the end customer.

Advantages of the Falling Film Chiller for Fruit and Vegetables

1. Water cooling by industrial water chillers for fruits and vegetables down to 0~1°C ice water temperature.

2. Open system, cleaning possible of these water chillers at any time even during operation, thus optimal hygiene.

3. Product particles in the warm return water do not lead to freezing. There are no inaccessible corners and angles that make cleaning difficult.

4. Minimal cleaning effort due to self-cleaning effect of the plates in these cooling ice water chillers due to constantly falling water film.

5. Icing due to irregularities in the compressor cannot cause mechanical deformation of these cooling water chillers.

6. Simple ice water system, no seals, no spare parts, i.e. no additional costs due to running times.

7. Fruit and vegetable coolers can be easily installed above any industrial cooling assembly line.

8. All parts made of stainless steel. Complies with all industrial cooling hygiene standards for fruit and vegetable coolers worldwide.

9. No risk of freezing with ice water cooling of 0~1 ° C for the hydro coolers.

10. Enclosed design prevents product contamination of this industrial water cooling heat exchanger.