Is the production process and technology of Chemequip Industries constantly updating?

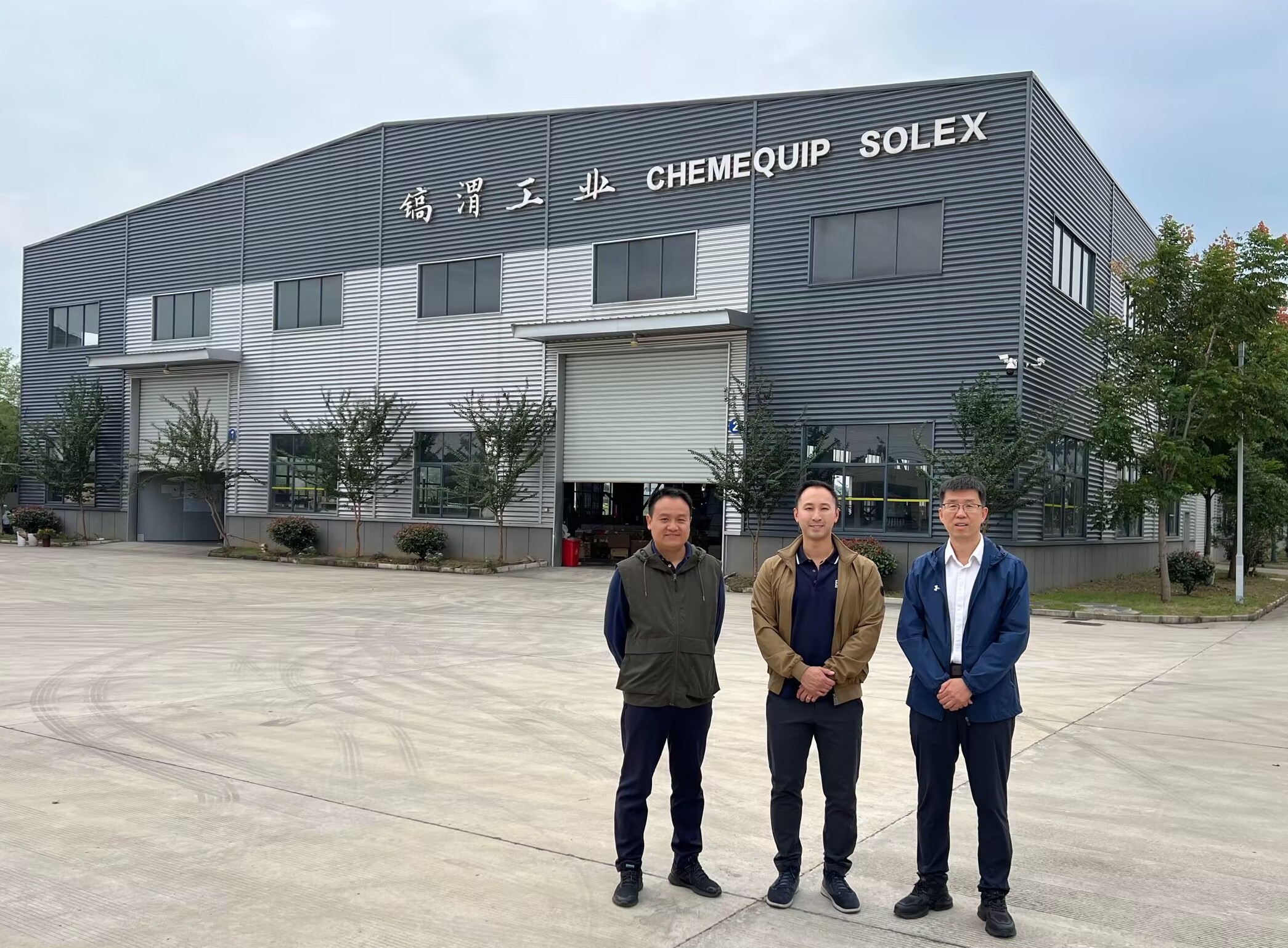

Yes, absolutely. We met with Canada Asia Representative on October 9, 2023, who is a is an expert in the field of cooling equipment for solid particle cooler and a cooling method for solid particles. In industry, when producing solid particles, a cooler is often used to cool and obtain the desired properties of solid particle products. For example, based on a technical and economic comparison with the heavy soda ash cooling technology used in traditional soda ash plants, it was demonstrated that the powder flow heat transfer technology is completely feasible for design and use in large-scale soda ash plants. In the alumina industry, at present, there are several problems with fluidized bed coolers: 1) Fluidized air and circulating water cooling tower fans require a significant amount of power consumption; 2) The heat emitted by circulating water cooling into the atmosphere is not utilized, wasting a large amount of thermal resources and polluting the environment; 3) The increase in production in the roasting furnace resulted in insufficient cooling area of the existing fluidized bed cooler, resulting in a material temperature higher than 80 ℃; 4) The casting material inside the roasting furnace lining falls off and enters the fluidized bed. Large pieces of casting material often damage the breathable cloth, causing compressed air to pass through the damaged breathable cloth holes and form an aluminum oxide powder jet, causing erosion and damage to the cooling pipes inside the bed; Small pieces of castable are deposited at the bottom of the fluidized bed to a certain thickness, preventing the aluminum oxide powder inside the bed from fluidizing; 5) It is very troublesome to clean the aluminum oxide powder inside the bed during maintenance and repair of the fluidized bed. However, during cleaning, the aluminum oxide powder leaks around the fluidized bed, causing alumina loss and environmental pollution.

Chemequp will persevere in deepening our efforts in the fields of Powder Flow Heat Exchanger, Bulk Solids Heat Exchanger, also in Nitrate and Nitrate, Nitrate and Nitrate Cooler, Nitrate and Nitrate Heater, bulk solids cooler, urea cooler, compound fertilizer cooler, soybean heater, sugar cooler, plastic cooler, fertilizer cooler, NPK cooler, urea prill cooler, granular urea cooler, DAP cooler, PP cooler, sand cooler, chemical cooler, falling film chiller, immersion chiller, ice bank, static melting crystallizer, flue gas heat exchanger, pillow plate, dimple plate, dimple jacket, clamp on, tank with clamp on, slurry ice machine, fluid ice machine, corrugation plate, pillow plate heat exchanger, etc.

Looking forward to the Chemequip Industries taking it to a higher level, hope we can make progress together.

Post time: Oct-10-2023