Professional China Solid particle heat exchanger – Bulk Solid Plate Heat Exchanger – Chemequip Industries Co., Ltd.

Professional China Solid particle heat exchanger – Bulk Solid Plate Heat Exchanger – Chemequip Industries Co., Ltd. Detail:

It is actually our accountability to satisfy your needs and effectively serve you. Your pleasure is our best reward. We’re on the lookout forward for your stop by for joint growth for Blocked Plate Heat Exchanger , Laser welded platecoil heat exchanger , Double embossed dimple jacket , Inspired by the rapid developing market of the fast food and beverage consumables all over the world , We are looking forward to working with partners/clients to make success together.

Professional China Solid particle heat exchanger – Bulk Solid Plate Heat Exchanger – Chemequip Industries Co., Ltd. Detail:

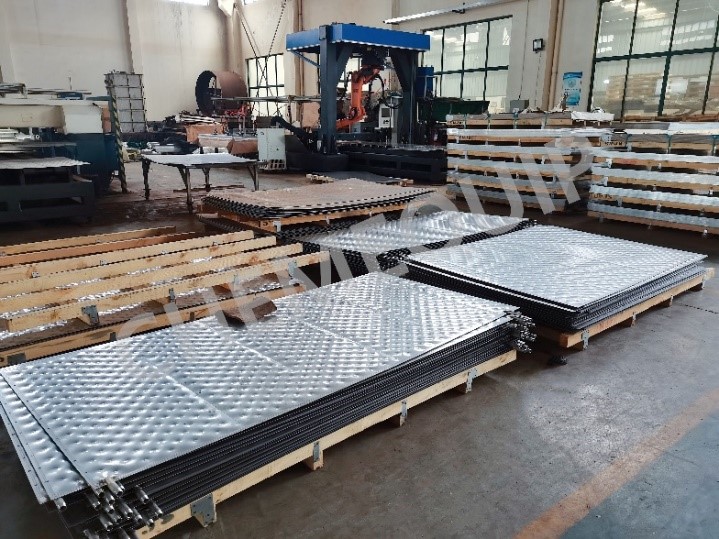

Bulk Solid Plate Heat Exchanger is a kind of plate type solid particles indirect heat transfer equipment, it can cool or heat virtually every type of bulk granules and powder flow products.

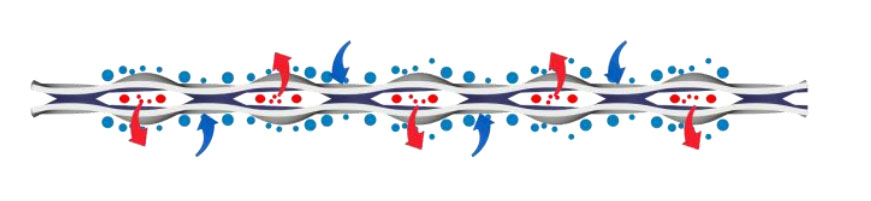

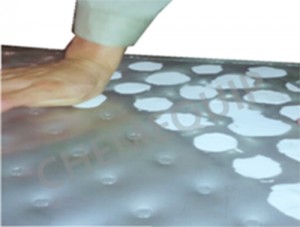

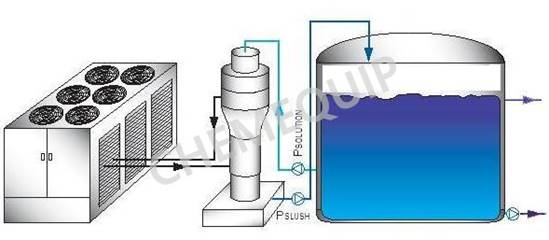

The basis of the bulk solids heat exchanger technology is the gravity flow of product moving through a bank of laser welded plates heat exchanger.

1.In the bulk solid plate heat exchanger, the vertical bank of welded heat exchanger plates cools the water flowing through the plates (counter-flow to the product flow).

2.Bulk solids pass slowly downward between the plates with adequate residence time to provide effective cooling of the product.

3.Indirect cooling by conduction, no cooling air is required.

4.A mass flow feeder regulates the solids flow at discharge.

Bulk Solid Plate Heat Exchanger can be widely used for most of solid and powder flow:

Fertilizers – Urea, Ammonium Nitrate, NPK

Chemicals – Ammonium Sulphate, Soda Ash, Calcium Chloride

Plastics – Polyethylene, Nylon, PET Pellets, Polypropylene

Detergents and Phosphates

Food Products – Sugar, Salt, Seeds

Minerals – Sand, Resin coated Sand, Coals, Iron Carbide, Iron Ore

High temperature Materials – Catalyst, Activated Carbon

Bio Solids Granules

When our Bulk Solid Plate Heat Exchanger compares to air cooling (rotary or fluid bed), its obvious advantages:

Bulk Solid Plate Heat Exchanger can achieve the efficient cooling without emissions

Bulk Solid Plate Heat Exchanger is gentle handling (low velocity)

Bulk Solid Plate Heat Exchanger has lower energy consumption

Bulk Solid Plate Heat Exchanger use pillow plates heat exchanger with low maintenance

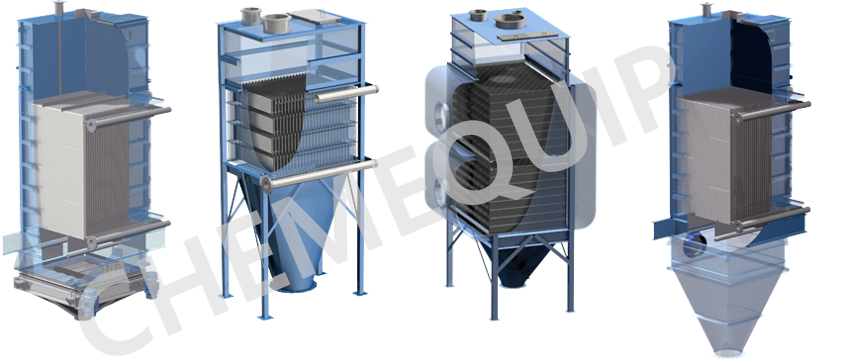

Bulk Solid Plate Heat Exchanger is vertical compact design with small area occupied

Bulk Solid Plate Heat Exchanger is a simple system without move parts.

Bulk Solid Plate Heat Exchanger has been widely applied to various solid particles heat exchange application: