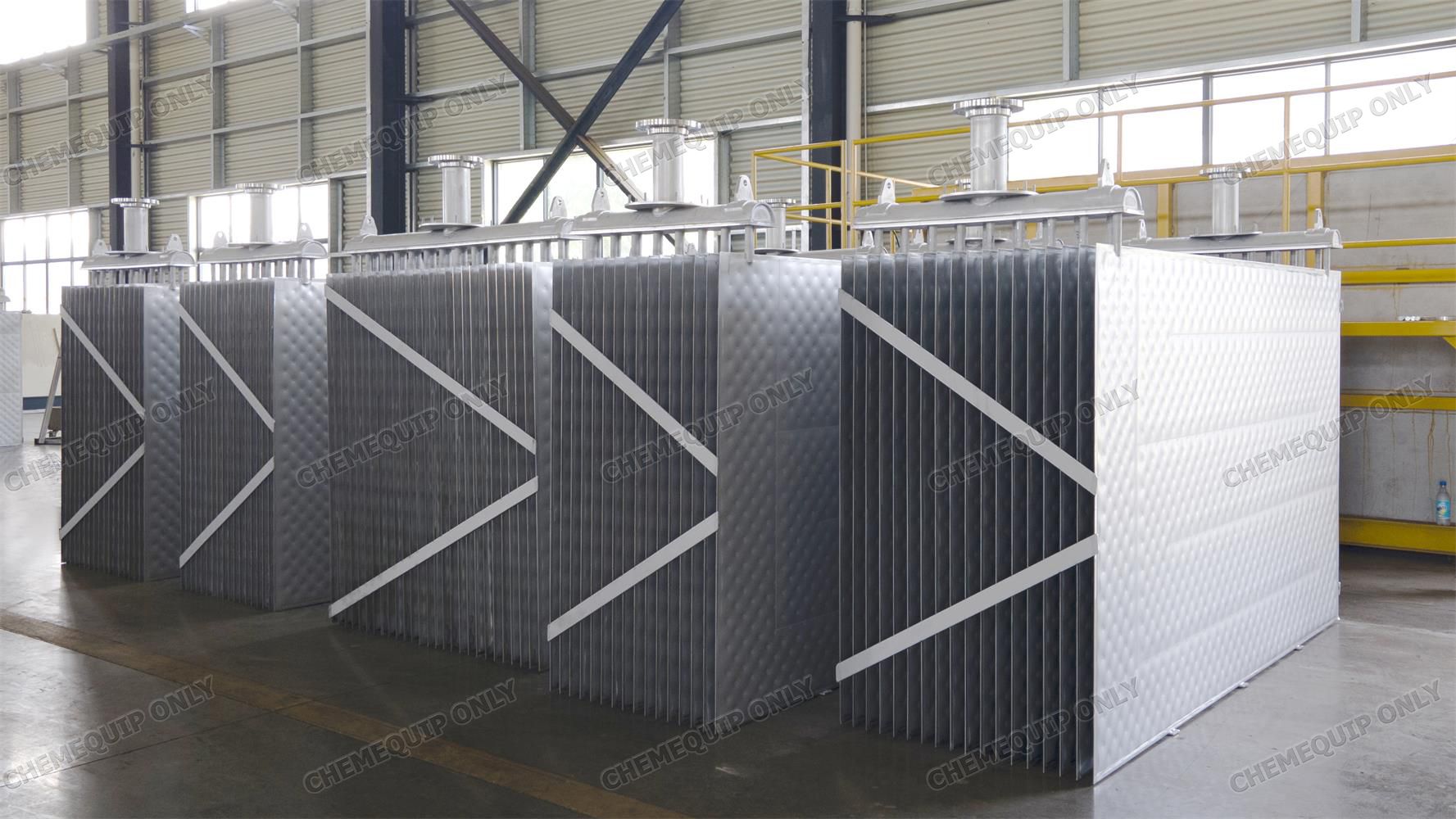

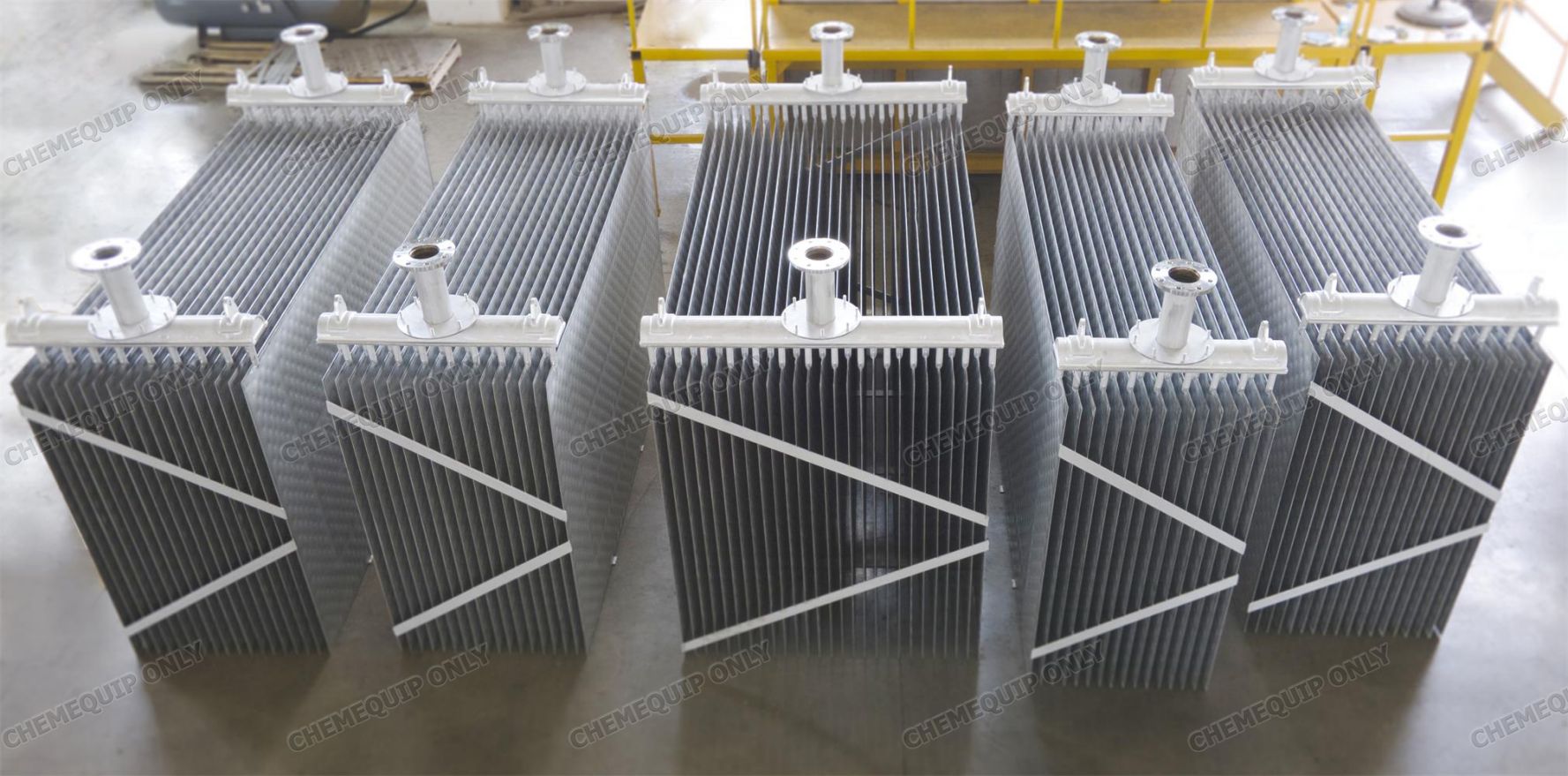

I-stastic inyibilika i-crystalwizer eyenziwe nge-dimple pilmer putter ubushushu

I-static cystallizer isebenzisa ipleyiti yokutshintsha kwe-upersung (iplate yeplate) kunye nendawo yokufudumeza okanye epholileyo, esetyenziselwa ukufudumeza ngaphakathi okanye inkqubo yokupholisa. Ubushushu beepleyiti zobushushu bubekwe ngokuthe nkqo kwiKhabhinethi yeCarstallizer, ukufudumeza okanye ukupholisa i-heats okanye ukupholisa i-crystalter i-mana ingezantsi kwento ethambileyo. Okokugqibela, i-crystality yoludwe lwenziwe kumhlaba otshintshiselwano lobushushu, isebenzisa inkqubo "yokubika" yokususa ukungcola kwaye ihlanjululwe iikristali.

I-stastic Melstallizer yindlela yokucoca kwaye yahlule imveliso ejolise kwezinye izinto ngokusebenzisa indawo yawo eyahlukeneyo (i-Crystallication ngokuthintela amanyathelo amathathu aphambili, ukuthuka kunye nokunyibilika.

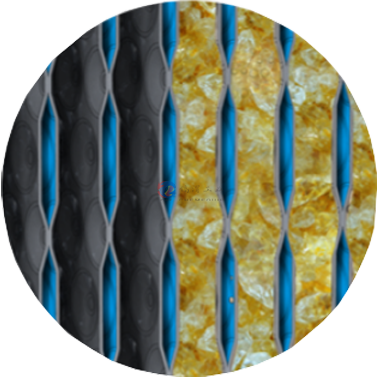

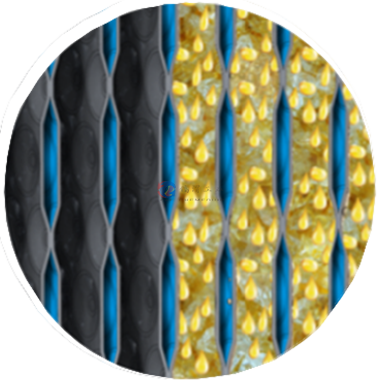

Umxube we-molten uphononongwe ngokuthe chu kukudluliselwa kobushushu ukuya ngasezantsi kwendawo yokunyanzeliswa kweekhilomitha kunye neekristali zithintela umphezulu weepleyiti zeplate yeplate, ukwenza amakristali. Ukungcola ikakhulu kunotywala mazwe kwaye kukhutshwe kwikristali.

Umaleko wekristali unokuhlanjululwa ngokufunga (ukunyibilika kwenxalenye), okt ukufudumeza ngokucothayo kwindawo yokunyibilika, emva koko ukungcola okufakwe kwimveliso kuya kunyibilika. Ukufunga linyathelo eliphambili kwinkqubo yonke.

Emva kokufudusa, ubushushu botshintsho lobushushu buphakathi lunyuke luye lwanyibilika bonke ungqimba lwe-crystallization kwaye ufumane imveliso ephantsi yemveliso ephantsi.

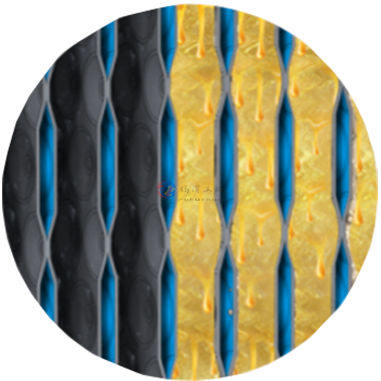

Iplate ye-platecoil ibubushushu obukhethekileyo i-fack yeplate, yenziwa yi-Laser Peechnolojing yeTekhnoloji kwaye ihlulwe, ngenxa yokuhanjiswa kobushushu obuphakathi kunye nokusasazwa kobushushu obuphakathi. I-LT ingenziwa kwaye yenziwa kwiimilo ezahlukeneyo kunye nesayizi ngokweemfuno zabathengi. Iplate ye-platecoil ibekwe kwindawo enamandla aphezulu. Itekhnoloji idibanisa uyilo lwe-proprietal anti-crapring of i-crystal ye-cerstial kunye ne-tecking yendawo efileyo ezantsi. Ingaphandle le-platecol yeplate yeplate yeplate yepleyiti (i-stastic crystallizer) yikhasishini eyilelwe ngemveliso engena kwimveliso, ikhuphe i-port, ikhuphe izibuko, izixhobo zokusebenza kunye nezinye ii-nozzles ezisebenzayo.

| Iikhemikhali zeBanga le-elektroniki | Iikhemikhali zePetroleum | ||

| Phosphoric acid | I-Carbonate carbonate | Iparaxyne | Benzene |

| I-Acetostitrile | I-Vinylidene carbonate | I-1,2,4,5,5-tetramethylbenzene | Phenol |

| I-Dimthyl Carbonate | I-Fluororodene Carbonate | Dicyclopentadiene | Iparafini |

| I-polymer monomers | Iikhemikhali ezintle | ||

| I-DL-i-lactive | I-bisphenol a | I-PYIrine | Tdi |

| I-Dinkerobenzene | m-xylyledine | I-Benzoic acid | Mdi |

| Succineonriitrile | I-metacrylic acid | I-chlorocetic acid | Naphthalene |

| I-1,4-i-butanediamine | I-gracical acid | I-1-naphthol | p-cres |

| I-1,4-dicyanobutane | I-Dimyethyl isuse | I-methylnaphthafelen | I-Benzoic acid |

| I-1,6-diaminoheXane | Terephthaloyl chloride | I-cyanoputiridine | I-4-chloroofaene |

| I-1,5-pentadine | I-BIS (4-FLOORORPONL) -Uthanone | Menthol | I-annehydride |

| I-Benzenediamine | I-BIS (4-nitrophenyl) I-ether | Diisocyanate | I-chloronitrobenzene |

| I-caprolactam | I-Dimyethyl Terephhthalate | Dicyclopentadiene | p-tert-bhylphenol |

| Ii-biochemicals | |||

| Oleic acid | I-Malic Acid | I-Butane-1,2-diol | Erythrit |

| I-itaconic acid | Steric acid | I-crotonic acid | lsosongel |

| Cinenamic Acid | Xylilil |

| |

1. Ukuhanjiswa kobushushu obungafaniyo.

2. I-Crystallication ye-crystallication.

3. Akukho kuwa kweekristale ngexesha lokufunga.

I-4. Ikhutshelwe ngokupheleleyo ukucoca kunye nokugcinwa.

I-5. Ubungakanani owenziwe ngokwesiko kunye nobume bufumaneka.