I-Bulk Fallids Bush olwenziwe ngeebhanki zomqamelo

I-Bulk Slous Subssern ibizwa ngokuba yi-Countraler Roles, iplate eqingqiweyo ye-Deada ye-Canada ye-Canary Andround kwaye iqinisekisile indawo yokuvelisa efanelekileyo kwaye iqinisekisile ixesha lokuhanjiswa.

I-1. Kwi-Bulk Speef Proper Pleick Translarn, iBhanki ethe nkqo yoBushushu be-Weldied Speed Pletser ipholile amanzi ahamba ngeepleyiti ezihambahamba kwi-Pletter (i-counter-iqhina lokuhamba kwemveliso).

I-2. Iinyibiliki ezininzi zidlula kancinci ezantsi phakathi kweepleyiti ezinendawo yokuhlala efanelekileyo yokubonelela ngempumelelo kwemveliso.

3. Ukupholisa ngokungathanga ngqo ngokusebenza, akukho moya wokupholisa uyadingeka.

I-4. Intshukumo enkulu yokuhamba ilawula iinyibilikisi ezihambayo.

I-Sollex Bulk Bolids Ubushushu (i-Suby Rush Grounter) ifakwe ngaphezulu kwe-Aurean kunye ne-Ammonium, i-Ammon, i-Ammonium, njl. Njl., Njl njl. amanzi.

1. Phakamisa iqondo lobushushu lokupakisha ngezantsi kwe-40 ℃, ukusombulula ingxaki yendlela.

2. Nciphisa ukusetyenziswa kwamandla kunye nokuphuma.

I-3. Uyilo lwe-compt enenkqubo elula.

4. Kulula ukufaka ngendawo encinci efakiweyo.

5. Ukonyusa ukhuphiswano lwezityalo.

I-6. Iindleko zolondolozo eziphantsi.

1. Ubushushu obuphezulu bupakishe bubangela i-verades kunye neekeyiki ngexesha logcino.

I-2. Ukusetyenziswa kwamandla hayi okuzinzileyo ngenxa yenzuzo ephantsi yenzuzo.

I-3. Ukukhupha ngaphezulu kommiselo omtsha womgangatho.

I-1. Izichumisi - Irea, I-Ammonium Nitrate, i-NPK.

2. Iikhemikhali - I-Ammonium sulphate, iSoda Ash, Calcium chloride.

I-3. IPlastics-Polythylene, inylon, i-pellets yezilwanyana, i-polypropylene.

I-4. Iicoci kunye nee-phosphates.

I-5. Iimveliso zokutya-iswekile, ityiwa, imbewu.

I-6. Iimineralis - Isanti, isanti enamalahle, amalahle, i-iron carbide, i-iron ore.

7. Izixhobo zobushushu obuphezulu - i-catalyst, ikharbon esebenzayo.

I-8. I-Bio Sliales ye-Sliales.

I-1. Unokufikelela ekufezekiseni ngokufanelekileyo ngaphandle kokukhutshwa.

I-2. Ukuphathwa kakubi (i-velocity esezantsi).

3. Ukusetyenziswa kwamandla asezantsi.

I-4. I-Plomer Plates Uprinta i-Deringer ngesondlo esiphantsi, ilula ukucoca.

5. Nkqo i-compact rict enendawo encinci yokuhlala.

I-6. Inkqubo elula ngaphandle kwenxalenye eshukumayo.

I-7. Uthintelo kunye noThintelo.

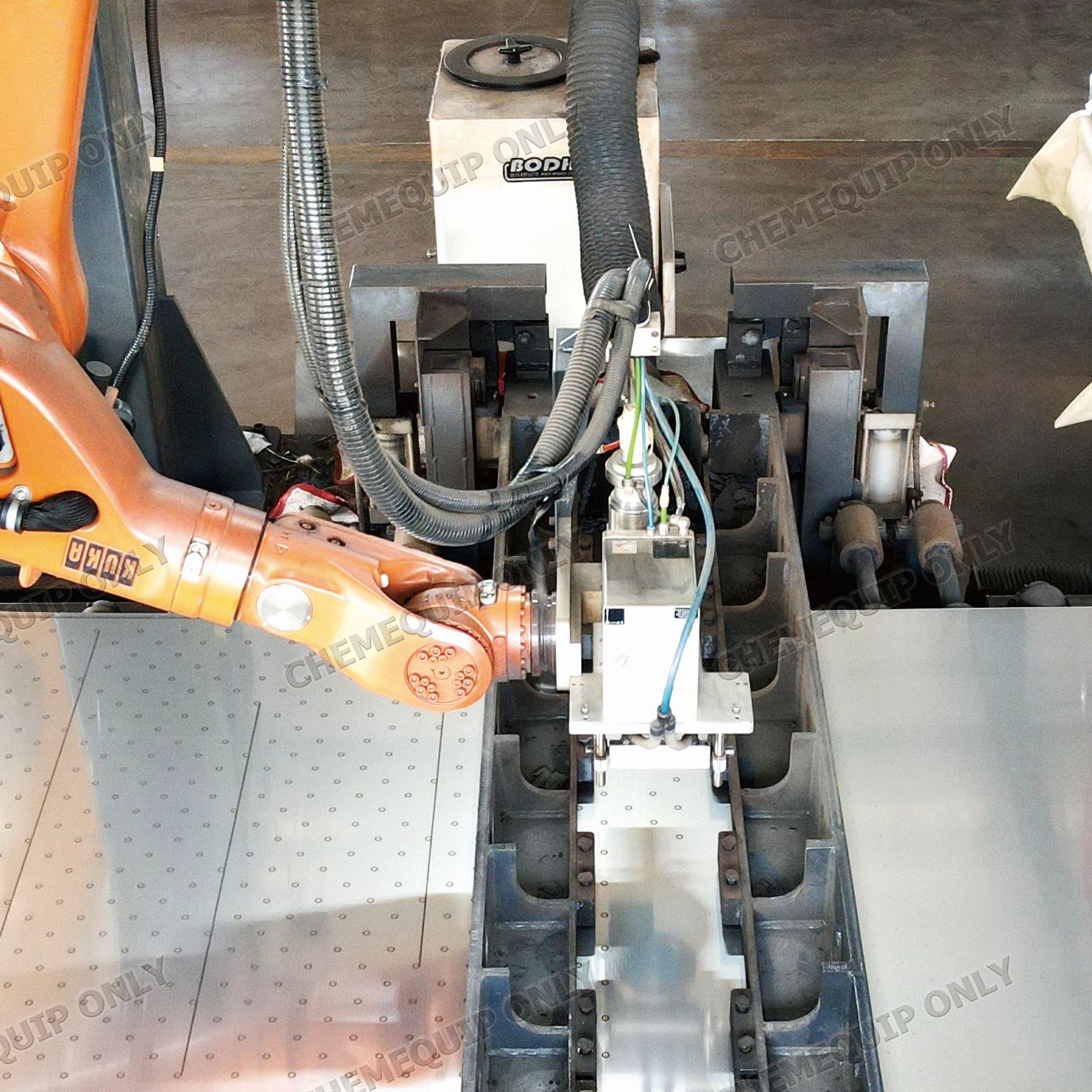

Iplate ye-platecoil ibubushushu obukhethekileyo i-fack yeplate, yenziwa yi-Laser Peechnolojing yeTekhnoloji kwaye ihlulwe, ngenxa yokuhanjiswa kobushushu obuphakathi kunye nokusasazwa kobushushu obuphakathi. I-LT ingenziwa kwaye yenziwa kwiimilo ezahlukeneyo kunye nesayizi ngokweemfuno zabathengi.