Manufacture laser welded heat transfer plate as a sample

Step 1 Design

| Name | Specification | Brand | Material | Heat Transfer Medium | |

| Laser welded heat transfer plate is designed according to customer requirements. | Length: custom-made Width: custom-made Thickness: custom-made |

Customers can add their own logo. | Available in most materials, including 304, 316L, 2205, hastelloy, titanium, and others | Cooling Medium 1. Freon 2. Ammonia 3. Glycol Solution |

Heating Medium 1. Steam 2. Water 3. Conductive Oil |

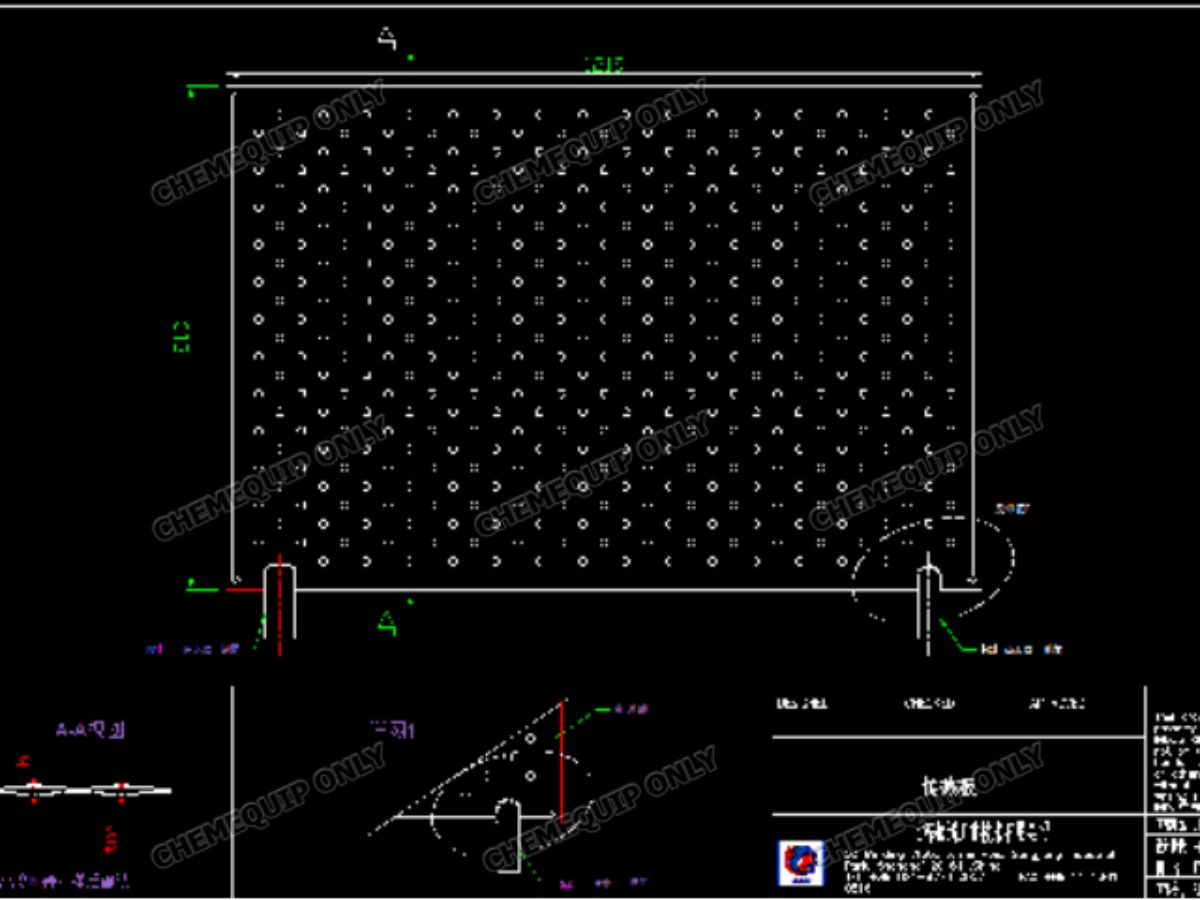

Step 2 Drawing

Chemequip will provide drawings for approval after the project is confirmed.

Step 3 Prepare and cutting material

Prepare the raw material according to the requirements.

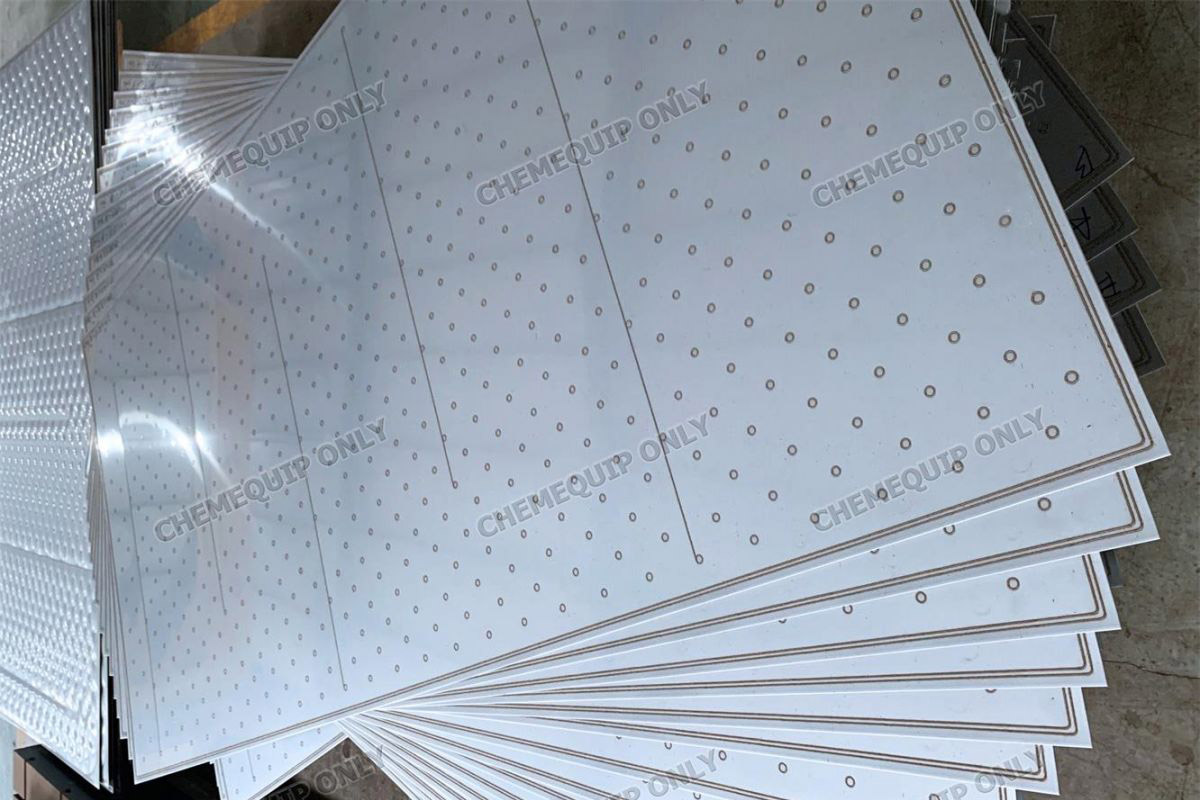

Step 4 Laser Welding

Laser Welding is done in the flat position by a process of welding a top sheet to a bottom sheet. This process is accomplished with no alteration to the product side of the bottom sheet such as pocking, pitting or discoloration.

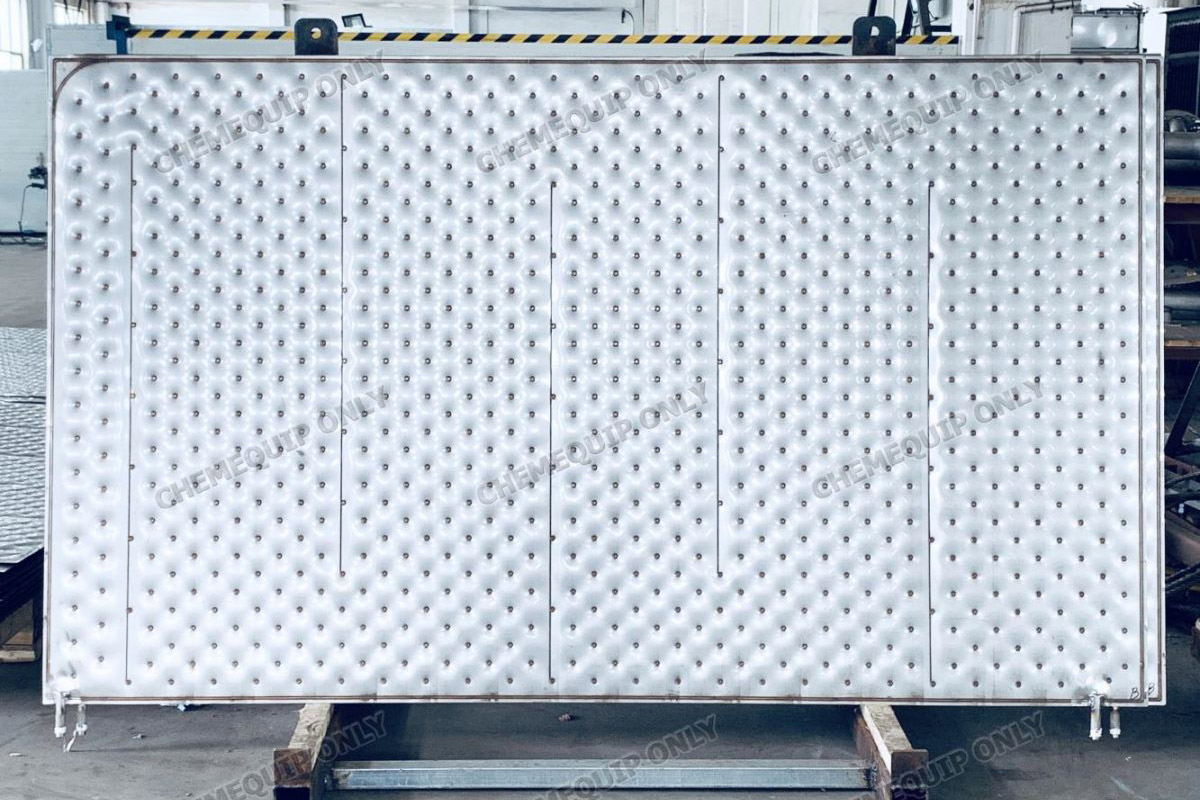

Step 5 - Forming

The laser welded panels are then formed into some shapes according to your design. For example:There are no additional requirements for forming laser welded jacketed materials. Heads can be formed as dished or coned shapes.

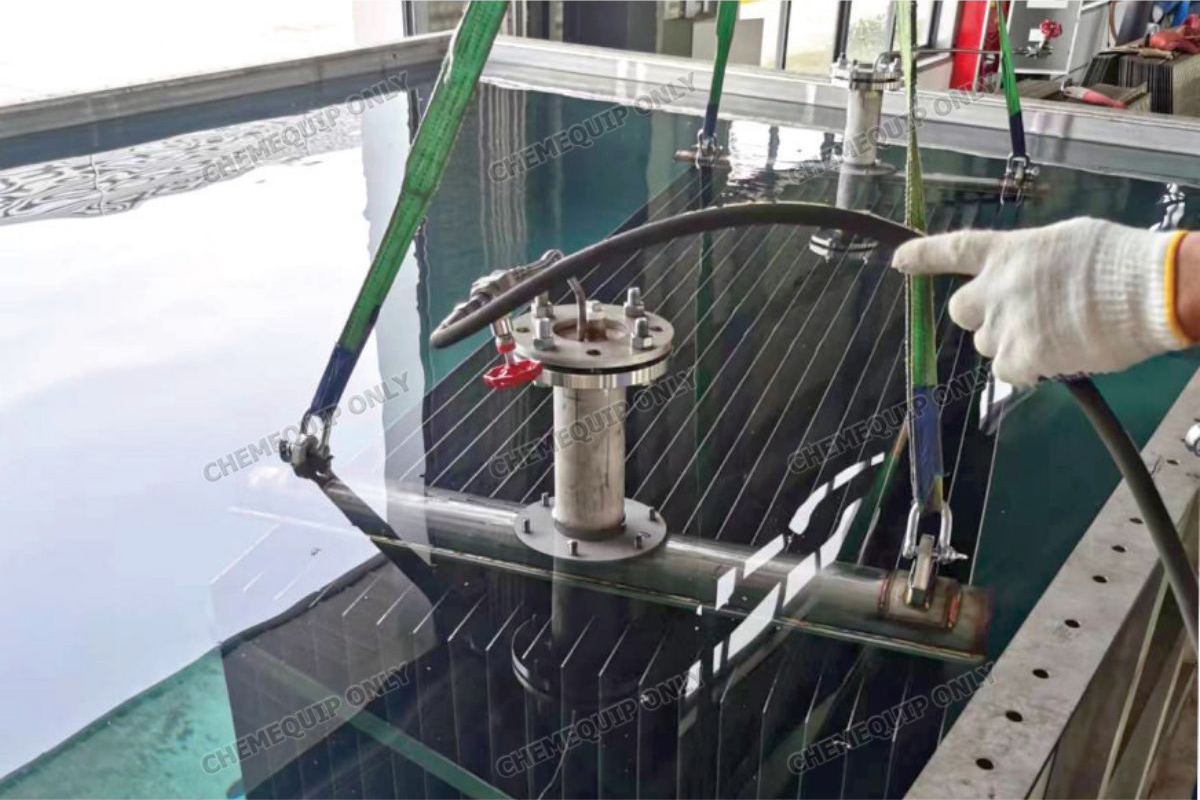

Step 6 - Nozzle installation and inflation

Install inlet and outlet pipes.

Step 7 - Testing

Leak test and so on before shipping.

Step 8 - Package

Packing in accordance with international shipping standards.

Equipments Manufacturing Site